How PLM can make a difference to combat Fast Fashion

by Coats Digital

Relentless consumer demands for instant, omni-channel availability of newness, and more recently personalisation, are major industry disruptor which demand process as well as product innovation.

In recent years, rising consumer expectations of constant newness, has led fashion businesses to deviate from traditional models of designing and developing for two rigidly defined seasons. Instead, many successful businesses are now developing several collections, commonly coined as ‘phases’ within a season, and tailoring these more specifically towards in-season trends, as they seek to maximise full price sales and minimise inventory. The result is an exponential increase in the demands placed on product development and sourcing with more inspiration trips, the hunt for new fabrics, trims and blocks, more fits and samples development, and even more time spent in beloved sign-off meetings! The ability of fashion businesses to manage this increase in workload and complexity, with a fast and efficient product development process, is increasingly a key strategic differentiator marking out the winners from the losers and that is where PLM can help.

One of the most common obstacles to reducing design & development lead time and increasing speed to market, is the ability to convert a design concept into an approved product with all of the materials, fit, construction and performance attributes developed, tested and available when a purchase order is issued. In today’s ‘typical’ fashion model, a technical designer interprets a designer’s expectations and brand character into a sample request and tech pack. The pattern-maker and/or product merchandiser, often located thousands of miles away, will use this to develop an initial pattern, find appropriate fabric and trims and make a sample they think meets the designer’s expectations. Some of this process can be accelerated using 3D sampling, but typically there are multiple iterations of a physical sample which require tweaks and approval. This is a hugely time consuming and expensive process, and standard tools and efficient processes can mean the difference between meeting the launch date and taking advantage of what’s ‘hot’ to maximise full price sales, or missing the launch date and losing out to competitors, or facing the prospect of excess stocks or significant mark downs.

In the face of these challenges, there is an increasing recognition that the largely manual processes and disconnected systems used by many fashion businesses to manage product development and sourcing, are reaching a breaking point. The current approach is simply not capable of providing the fast access to accurate information that is key to better decision making and sustainable competitive advantage. It is, perhaps, surprising that the industry has been relatively slow to adopt technology in an area which has such a profound impact on speed to market, sales and margins, but this is changing fast as the pressure of market demands builds. Coats Digital provides proven fashion industry expertise and a trusted browser-based PLM, which allows streamlining of key business processes, improving visibility, coordination and control, and increasing the speed and efficiency of product development and sourcing, which is so critical to maximising sales and margin.

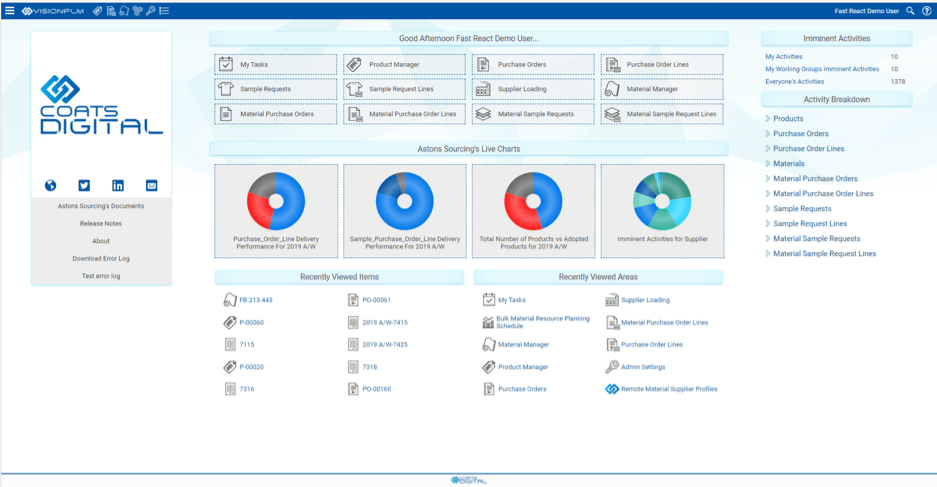

VisionPLM

VisionPLM is a highly intuitive, modular solution, which allows businesses of all sizes to improve the speed and efficiency of key business processes from range planning and design inception, through BOM, costing and tech pack creation, to sampling, PO tracking and supplier collaboration. Here we look at just a few examples of what VisionPLM means in practice.

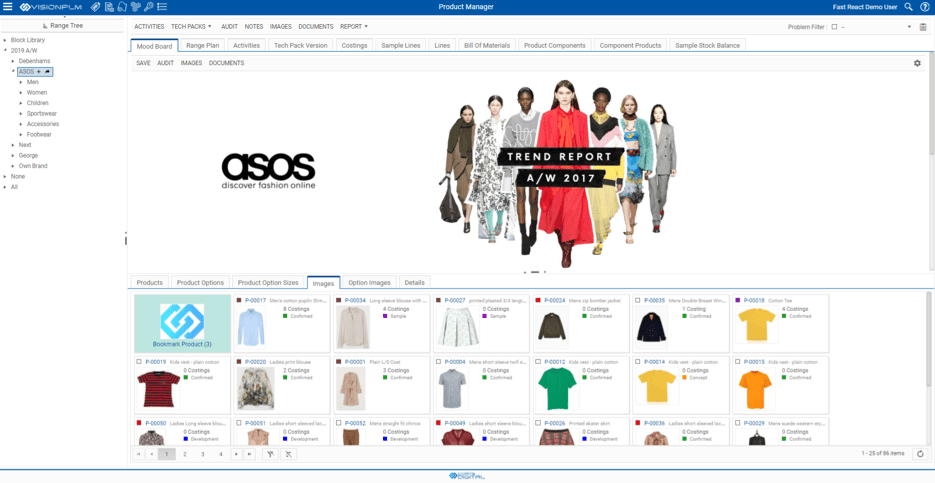

Product Design & Development

The natural fear of many design teams is that a new system will mean more administration and less creative time. The reality is that VisionPLM is directly integrated with Adobe Illustrator, so designers can remain in their primary design tool and focus on being creative. At the same time, critical information about the design and product is captured from the start (with key information pre-populated or quickly selected from drop-downs) and automatically passed to VisionPLM so that other members of the product team have instant visibility. What this means is no more duplicate keying into multiple systems and spreadsheets, and with in-system mood boards and clear targets for styles, options, price points and margins from the range plan, designers can be more creative, more focused, more productive and happy!

Tech Packs/Workbook

In the early days, when PLM was PDM, it was all about the Tech Pack/Workbook, and this clearly continues to play a critical role in ensuring that our manufacturers have all of the information that they need to make a product to the correct specification, on time and to cost.

With direct links to a material library, VisionPLM is a trusted PLM for the fashion industry and ensures that designers are able to effortlessly look-up and specify fabrics and trims to be used in the BOM, or create and add materials ‘on the fly’, along with that all important ‘approval status’, ensuring that garment manufacturers only make fully approved product. Many of us will be regrettably familiar with the situation in which an unapproved product has slipped through the net resulting in lost time, money or the hugely embarrassing situation in which a product is presented in a sign off meeting but cannot be delivered commercially!

Should that moment come where a material (so often the key material of the season) fails its testing, VisionPLM’s ‘where used’ functionality, or the BOM summary grid, make it is simple to identify those styles which are affected and update BOMs.

Size specifications, make up methods, labeling and packaging information are the final ingredient to the tech packs. VisionPLM can generate these within system, ensuring uniformity and minimal data entry, as well as the ability to look-up pre-existing libraries of information, ranging from previous size specs and care label references to different packaging types. All of this means less manual keying of data and ‘copying and pasting’ between multiple spreadsheets, and the inherent issues with data integrity and errors which are an almost unavoidable part of daily life with manual systems.

VisionPLM has full version and change control providing visibility of what was changed, by who and when, as well as the ability to save different versions so that all product team members, both internally and externally, are working from the same and latest version of key documents.

“We are looking forward to working with Fast React (now Coats Digital) on a project which will improve the speed and efficiency of our product development and sourcing processes, supporting further growth and allowing us continue to differentiate ourselves from the competition by delivering aspirational, affordable luxury bags and accessories.”

Jayne Worden, CFO Radley

Sample Requests and Fits

The sample management module and fit logs work in tandem to draw on information already in system. This allows streamlining of processes such as recording sample fits, with the fit log for the sample being automatically pre-populated with the correct size information. Sample orders can also be raised, tracked, receipted and moved around the business from within VisionPLM, providing complete visibility of samples, both externally and internally, relative to the agreed supplier and internal critical path. No more samples going missing for those all-important buy-meetings!

Garment Costings

VisionPLM offers a comprehensive, easy to use and highly flexible costing module, with full CMT and FF costings management including ‘what if’ scenarios and margin ‘roll up’. Full currency conversion and a direct link to the materials library allows quick and efficient costing, easy ‘swap out’ of materials and comparison/change of suppliers. Garment Costings can be presented in multiple versions, with seamless supplier collaboration and updates.

Critical Path

If effective management of critical path is key to delivering product on time, on cost and to specification, should we really be relying on largely manual processes and multiple spreadsheets? Almost certainly not!

VisionPLM offers best in class critical path management software through the full development lifecycle of a style, including material, style, sample, product and PO. Smart workflow is used wherever possible, automatically updating the critical path where a development step has been completed, ensuring full visibility of the latest status by ‘simply doing the job’, rather than having to retrospectively and manually update critical path spreadsheets. The ability to ‘roll up’ critical path progress across a season/ collection/department etc., provides vital visibility across the business, and multiple options for easy supplier updates mean that this can be extended to the supply chain.

“As we enter the next phase of our growth, one of the key priorities for our business is to have a system in place which supports a more efficient design and development process, as well as enhancing supplier collaboration and management of capacity. Following an extensive review of potential vendors and solutions, we selected Fast React’s (Now Coats Digital) VisionPLM, not only for the user-friendly interface and functional fit of the software, but because we felt confident that we had identified a partner who would be able to add value beyond software and help us deliver best practice processes.”

Niki Pedder, Head of Product, Grana

Supplier Collaboration

Delivering a fast, efficient and effective product development process relies heavily on collaboration across departments and with suppliers. The latest style, sample and tech pack information can be accessed in system, with highly visual alerts and exception reporting, and can also be emailed directly from the solution, ensuring that the manufacturer has the right information at the right time, reducing lead times and increasing ‘right first time’ developments. VisionPLM also provides several practical and efficient ways in which suppliers can provide updates. Beyond conventional PLM, VisionPLM provides high level visibility of supplier loading (demand and supply) and detailed tracking of POs…more of this in a future sourcing paper!

Conclusion

Relentless consumer demands for instant, omni-channel availability of newness, and more recently personalisation, are major industry disruptor which demand process as well as product innovation. VisionPLM can provide the industry expertise and tools to support fashion businesses in responding quickly and efficiently to these demands, as well as maximising the potential of existing resources and your supply chain…

All Blog Categories

- Design and Develop

- Corporate

- Fabric Optimisation

- Method Time Cost Optimisation

- Production Planning

- Shop floor execution

- Supply Chain Solutions

- Sustainability

- Videos