Leading production planning and control for garment manufacturers

Dynamic planning of capacity, critical path and materials

FastReactPlan is the market-leading apparel production planning software solution, supporting a faster, more reliable order confirmation process and production plan which is optimised for delivery, speed and efficiency.

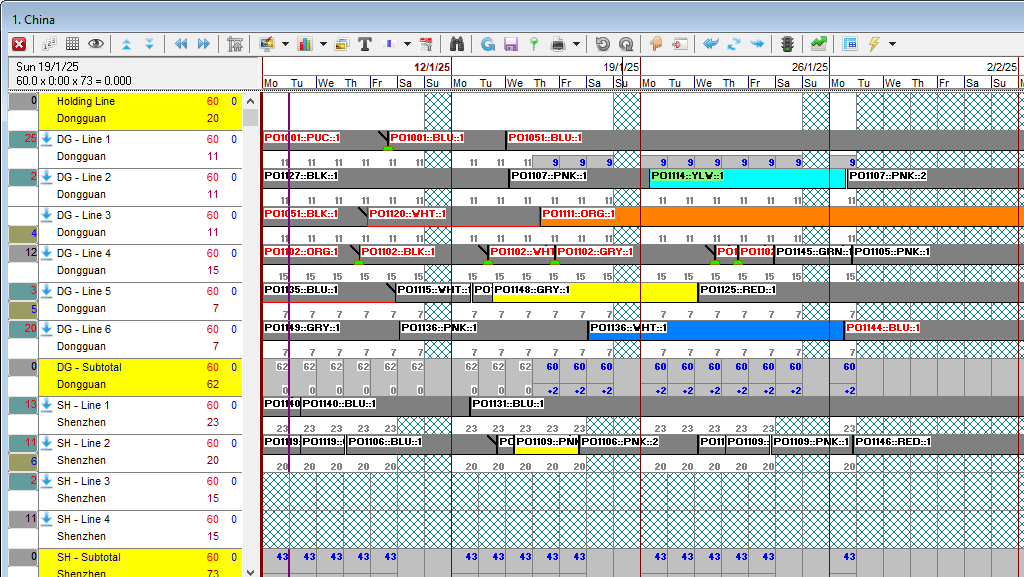

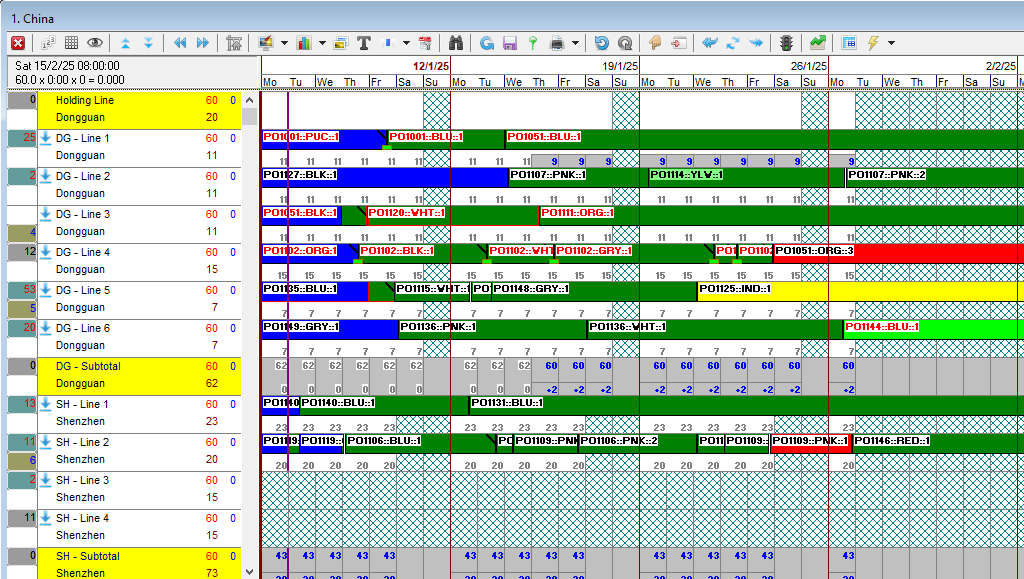

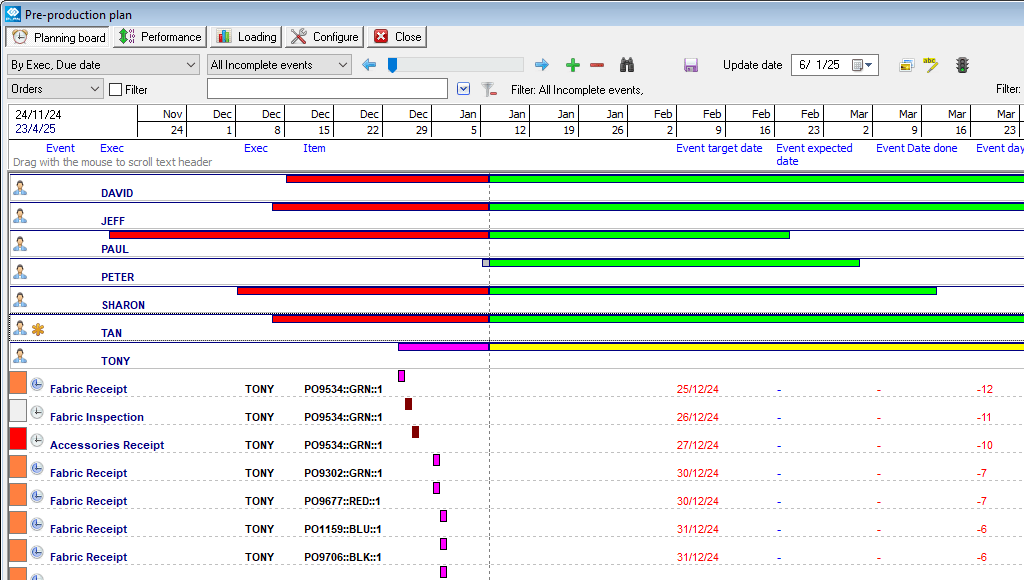

The highly visual, flexible ‘drag and drop’ approach to planning allows effective master planning across multiple factories, as well as fast, detailed and accurate scheduling of manufacturing lines/machines. Critical pre-production activities and material requirements are dynamically driven by the latest plan on a LEAN ‘just in time’ basis, supporting the reduction of inventory and lead time. FastReactPlan is proven to:

Proven and trusted

Reduce Planning Time and Increase OTDP with FastReactPlan

FastReactPlan tool is a production planning and control software system that helps Fashion businesses plan quickly and effectively to support the ever-changing needs of our customers in Apparel manufacturing and provide core foundation for business growth.

Typical business benefits

3 − 10 %

Increase in productivity

10 − 30 %

Improvement in OTDP

10 − 30 %

Reduction in lead time

“FastReactPlan supports the business improvement process by providing visibility and coordination to minimise errors and highlights potential problems quickly so that they can be immediately rectified before they become an issue.”

Managing Director, MAS Active

Key processes managed by FastReactPlan

What our customers say

Delivering real results

Customer testimonials

South Asia

#ProductionPlanning

Madura Garments increase operational efficiency by more than 7% in 2 years.

Madura Garments Exports, a subsidiary of the Aditya Birla Group, is one of the largest shirt manufacturers in India with…

South Asia

#ProductionPlanning

Brandix Group selects FastReactPlan to support strategic initiatives

As the leading apparel manufacturer looks to expand the business, they needed a solution that would strengthen their decision making…

South Asia

#ProductionPlanning

Epyllion increases delivery performance by 58% with FastReactPlan

The use of the integrated Critical Path management tools and the high-level control tower view for management and marketing teams…

South East Asia

#ProductionPlanning

Bodynits achieve a faster planning process with FastReactPlan to gain efficiency by 20%

Planning time reduced from 5-7days to 1 day. Planning became much more efficient keeping the same products on the correct…

Europe, Middle East, and Africa

#ProductionPlanning

Dewhirst achieves improved customer service with FastReactPlan

Marks and Spencer supplier Dewhirst have achieved improved customer service, speed of response and lower stock holding, through the implementation…

South East Asia

#ProductionPlanning

FastReactPlan digitally transforms Gold Emperor’s production processes

Coat Digital’s FastReactPlan has been selected to enable Gold Emperor to respond effectively to growing market demands, optimise its production…