Production shop floor execution

The bridge between the physical and digital,

proving the feedback loop for continuous improvement

The critical importance of digitizing your production shop floor

Unprecedented volatility, increasingly fragmented order books and a move to on-demand production, are driving greater complexity and margin pressure in the fashion supply chain. As manufacturers respond to these challenges, capturing and digitizing data in real time across end-to-end manufacturing processes is critical for driving actionable data insights and the feedback loop of performance to plan / standard which is fundamental to enabling early proactive actions, improving decision making and optimising operational and financial performance.

Why change?

Unlock the full potential of people, method and machine

The largely manual and siloed systems used to manage the complex end-to-end manufacturing processes are unsustainable, and simply do not provide the required level or speed of data insight that manufacturers and their buyers require. With multiple teams working (at speed) in parallel towards a shared goal, real-time data has never been more important. Manufacturers need to unlock the full potential of people, method and machine by optimising and digitizing key processes from machine inventory and line layout planning, to skills management, production tracking and quality management.

Explore the Res.Q suite of solutions and create a ‘digital copy’ of your shop floor

Typical business benefits

Capturing and digitizing data in real time across end-to-end manufacturing processes provides the rapid data insights which power improved decision making, driving significant, measurable and sustainable improvements in operational and financial performance. Typical business benefits include:

5 − 25 %

Reduction in quality defects

25 %

Reduction in machine rental

5 − 10 %

Improvement in efficiency

Shop floor execution solutions

Digitizing the core of smart factories

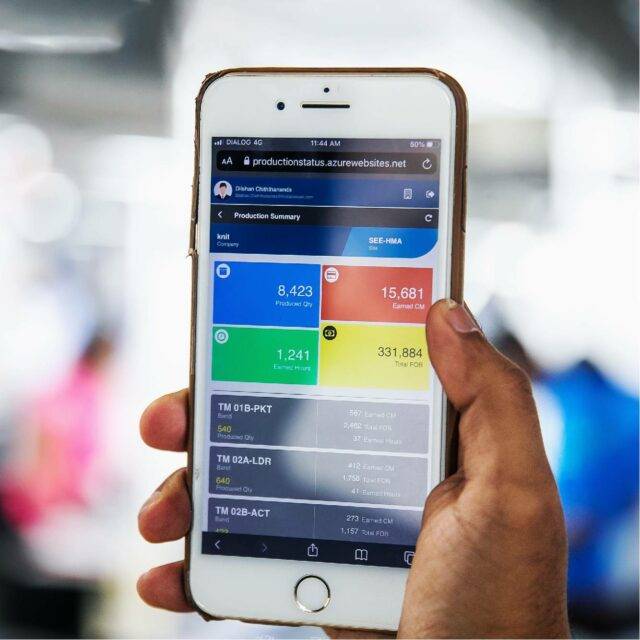

The Res.Q suite of highly visual, intuitive solutions, capture and digitize data in real time across end-to-end manufacturing processes. Res.Q provides rapid data insights, and seamless integration to other Coats Digital solutions for comparison of performance to plan / standard to drive continuous improvement.

Res.Q solutions are fast to implement, intuitive to use and proven to deliver significant and measurable improvements in speed to market, cost and productivity, supporting a typical return on investment of less than 12 months.

Get a Digital Copy of your Shop floor with Res.Q

Streamline processes and analyse your shop floor in real time with the industry-leading shop floor management software.