Esquire Knit Composite Ltd use FastReactPlan to improve control of pre-sewing processes resulting in 60% factory efficiency improvement

Improvements in capacity management and order control leads to reduced down-time and better delivery performance

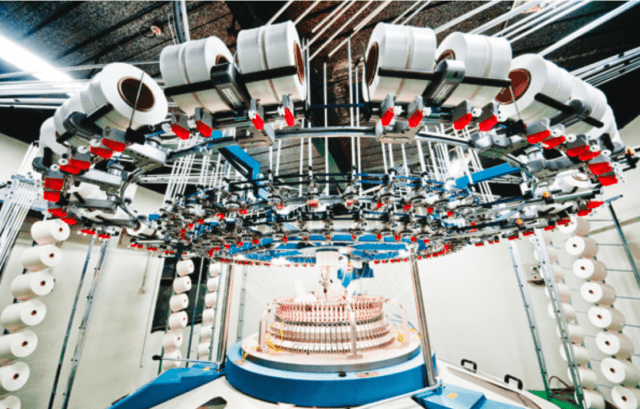

Esquire Knit Composite Limited was established in Dhaka, Bangladesh in 2001 and has grown into a successful vertical, world class knit garment manufacturer.

It has multiple business units covering yarn dyeing, knitting, fabric dyeing and finishing, printing, embroidery, sewing and garments dyeing and washing all under one roof. Specializing in embellished garments, Esquire supplies some of the world’s largest retailers including Esprit, C&A, Next and Best Seller.

6 %

improvement in efficiency

The challenge

“Our growing market share comes with a greatly increased level of competitiveness and complexity. Esquire produces more than 1.6 million pieces per month but order sizes are reducing, varying between 500 – 5000 pieces. In addition to coping with more styles, we have multiple types of embellishment to manage.

Kamal Munasinghe, CEO,

Our business needed enhanced control and visibility over all our operational areas. We selected Coats Digital as they are experts in this area, have a local team and the FastReactPlan solution could work well with our existing business system.”

Esquire Knit Composite

“It was clear that the pre-sewing areas, such as printing and embroidery, were the top priority for Esquire as 95% of orders required these processes but the team struggled to have visibility of capacity and WIP, and was not able to see problems quickly enough. This was resulting in bottlenecks, which led to idle time in the sewing lines.”

Rukunuz Zaman,

Project Manager, Coats Digital

The solution

Esquire Knit established a new centralised planning team around the FastReactPlan solution. Detailed line level sewing planning boards are used to manage production capacities for sewing, which in turn link to FastReactPlan’s operations management module. Using the pull system principle, FastReactPlan automatically creates detailed schedules for the different embroidery and printing types such as Glitter Print, Photo Print, Applique Embroidery and Sequin Embroidery, considering style and colour variations.

The planners now have clear visibility of the weekly load vs capacity for each machine group well in advance so they can ensure that sewing demand is achievable. Esquire can also check the ‘Plan vs. Actual’ and the ‘WIP level’ daily to ensure there are no last minute shortages.

“Planning in FastReactPlan has become much easier than the previous method of planning on separate spreadsheets. Planning and daily re-planning is a very quick process in FastReactPlan with a visual traffic light system highlighting the potential problems of late delivery, material in-house and production WIP issues.”

Pronoy Chandra Chanda,

AGM Planning, Esquire Knit Composite

The results

“By using FastReactPlan we have now integrated planning through all our functional departments. The feeding between the embellishment units to sewing units has become much smoother. By reducing our down-time we have improved our efficiency by 6%. Additionally, we have improved co-ordination between departments through a single system now we have instant real-time access to all the relevant information in a single source. The FastReactPlan reporting tool is very effective to identify potential problems and make proactive decisions accordingly.

Indunil Mahawatte, Head of MIS,

The FastReactPlan implementation process was smooth and the strong follow-up from the FastReactPlan team helped us to drive the project in the right direction to achieve business objectives within minimal time.”

Esquire Knit Composite

Gaya Karunathilake, COO, Esquire Knit Composite added “95% of our styles requires highly sophisticated embellishment, before FastReactPlan we regularly faced unforeseen bottlenecks which subsequently resulted in idle time. Now we can foresee these bottlenecks and each department is taking precaution to manage those well in advance.”

“It only took 5 months from system setup and configuration to establish FastReactPlan within the business, which has resulted in 6% factory efficiency improvement and a 5% improvement in Ship to Cut ratio.”

Kamal Munasinghe, CEO,

Esquire Knit Composite

Related testimonials

South East Asia

#ProductionPlanning

Nice Group improves efficiency and customer satisfaction with FastReactPlan

The leading sportswear manufacturer has been able to increase performance to plan from 80% to 91% and factory efficiency by…

South Asia

#ProductionPlanning

Ocean Lanka increase their daily production output through the use of FastReactPlan

FastReactPlan has allowed Ocean Lanka to prioritise and manage their activities to meet their increasing customer demands. This has improved…

Europe, Middle East, and Africa

#ProductionPlanning

Mission-led manufacturer DTRT Apparel uses FastReactPlan to set new sustainability standards

As a cornerstone of an ambitious, multi-year growth strategy, DTRT (Do The Right Thing) is leveraging FastReactPlan across all production…