Viet Vuong cuts fabric wastage by 2% and saves 3% in fabric cost with FastReactFabric

FastReactFabric additionally delivered BOM savings of 1.13%; overall wastage savings of 1.23%; optimised productivity and increased customer satisfaction.

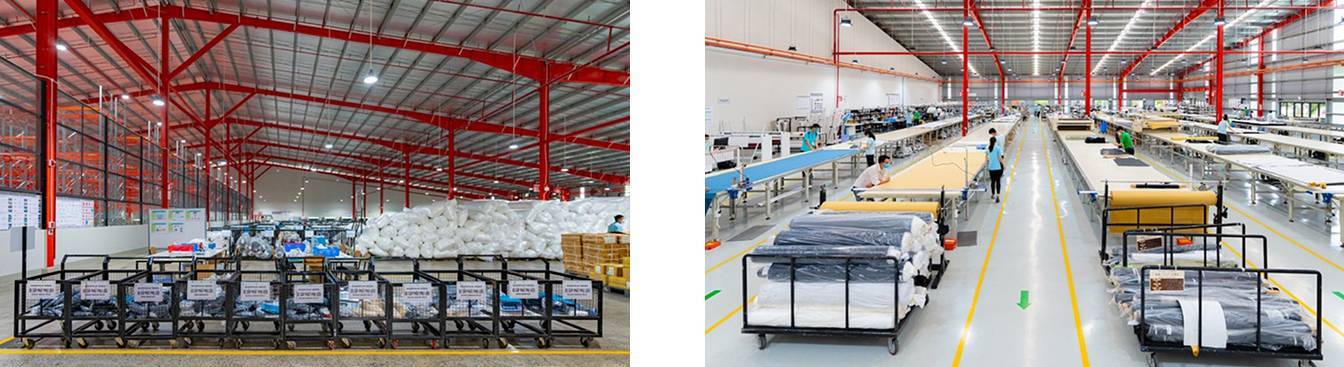

About Viet Vuong

Viet Vuong is committed to delivering sustainable manufacturing processes wherever possible and reducing its fabric wastage to zero is a top priority.

The company has secured recognition – for being a green-friendly factory from WRAP – a charity, working with governments, businesses and citizens around the globe to create a world in which resources are used sustainably; Better Work – which improves global garment industry conditions – and the sustainable building programme, LEED.

2.0 %

Reduction in fabric wastage

3.0 %

Fabric cost savings

1.13 %

BOM savings

1.23 %

Overall fabric wastage savings

The Challenge

Manual fabric assessment processes delivered incorrect data on material consumption, resulting in increased fabric wastage, costly additional fabric orders, and a litany of human errors. With no clear visibility on the cutting-room floor, management also found it difficult and time-consuming to make informed decisions about how to optimise fabric utilisation to reduce dead stock.

Manual fabric assessment processes delivered incorrect data on material consumption, resulting in increased fabric wastage, costly additional fabric orders, and a litany of human errors. With no clear visibility on the cutting-room floor, management also found it difficult and time-consuming to make informed decisions about how to optimise fabric utilisation to reduce dead stock.

Prior to implementing FastReactFabric ( Formerly IntelloCut ), Viet Vuong used Excel spreadsheets to assess and monitor its fabric costing and utilisation processes. This manually executed operation resulted in limited visibility into accurate fabric consumption calculations and unnecessary wastage due to a lack of available data regarding material usage on the production floor.

With no robust method in place to provide an accurate breakdown of fabric wastage, the management team at Viet Vuong found it difficult to make informed business decisions about how much fabric to buy to fulfil orders. If the company purchased more fabric than it needed, it would lose profit from dead stock; and if it bought less than was actually required, it would lose profit by having to buy in more material at its own expense, as these additional costs had not been factored into initial customer quotes.

The Solution

Following the implementation of FastReactFabric, Viet Vuong was afforded the full visibility and tracking of fabric consumption and wastage it needed to make factual data-based decisions about the fabric it purchased and how it was utilised. By digitising fabric costing and cutting processes, Viet Vuong significantly optimised its fabric utilisation rate to over 98% – reducing its fabric wastage to under 2%.

The solution significantly increased production efficiencies which meant shorter lead times for customers, but also greatly reduced the time and effort planning teams required to create capacity forecasts, freeing up more time to enhance customer satisfaction objectives overall.

Fundamentally, however, the implementation had a direct positive impact on the company’s bottom line, with Viet Vuong reporting fabric savings of nearly 3% and Bill of Materials (BOM) savings of 1.13%, from November 2018 when the solution was first implemented, to 22nd February 2022.

Before FastReactFabric, all the cutting data was spread between disconnected spreadsheets and emails, so it was difficult to compile the data to analyse key trends related to fabric consumption and wastage.

CEO,

With FastReactFabric ( Formerly Intellocut ), we have gained visibility over the entire cutting floor and through the intuitive real-time reports on fabric performance, we now have the ability to make data-backed decisions to optimise fabric utilisation, reduce wastage and ultimately support the sustainable growth of our business.

Viet Vuong Trading Co.Ltd

Coats Digital’s FastReactFabric is designed to give full control over fabric usage in the cutting room by optimising key processes, including: the generation of cut plans, lay plans and allocation, end bit usage, capacity planning/tracking and reporting. The solution’s automated, closed-loop approach to fabric planning reduces the amount of time and effort spent on planning and re-planning and maximises fabric utilisation on the production floor.as first implemented, to 22nd February 2022.

FastReactFabric helped us to establish an efficient fabric planning and cutting process by providing fast and accurate cutting execution plans as well as effective fabric tracking and real-time reporting of the cutting floor.

CEO

This has allowed us to eliminate error-prone manual processes, saving us a huge amount of time and effort.

Viet Vuong Trading Co.Ltd

FastReactFabric has allowed us to gain full control over fabric usage in our cutting department and with the ability to plan and re-plan the fabric based on real time cutting floor feedback, we have successfully reduced our fabric wastage to under 2% which is a great achievement for us and propels us towards our sustainability goals.

CEO

Viet Vuong Trading Co.Ltd

Adopted by over 150 manufacturers across 15 countries, FastReactFabric is infused with agile analytics and mobile technology that is designed specifically to help manufacturers optimise fabric utilisation and reduce fabric wastage.

Tan Demir, Associate Manager, Coats Digital added “It is great news that Viet Vuong has achieved such significant results since the implementation of FastReactFabric. The solution has not only increased Viet Vuong’s profitability, but also helped it realise a few of its ambitious sustainability targets, by reducing fabric waste and operational costs, which are all factors increasingly become uppermost in the minds of more discerning consumers.”

Smart Fabric Planning with FastReactFabric

Stop wasting fabric and start increasing profit. Buy fabric with accuracy and cut with confidence.

Related testimonial

South East Asia

#FabricOptimisation

FastReactFabric helps Song Hong to reduce 60% of fabric planning time

FastReactFabric accounts all the wastages on the cutting floor and reconciles the data in the reports for any desired date…

South East Asia

#FabricOptimisation

GJM (Luenthai) cuts fabric wastage to boost its top-line with FastReactFabric

GJM improves their processes to generate real-time optimised plans, fabric tracking and reports with the objective of boosting performance and…

South Asia

#FabricOptimisation

MBM Group increases fabric use by 1% and automates 72% of its cutting room processes with FastReactFabric

Coats Digital’s FastReactFabric provides MBM Group, Bangladesh with real time fabric planning and reporting automation to deliver an effortless approach…