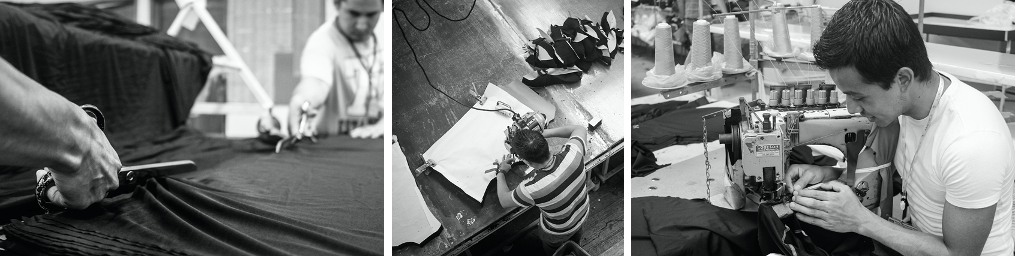

With over 20 years’ experience, Grumax is proud of its reputation as a reliable supplier, committed to its customers, its employees and the community. Based in Xalapa, Mexico, with over 600 employees, Grumax produces sports apparel for some of the most recognised global sports apparel brands, including Under Armour, Decathlon, Speedo and Calvin Klein, as well as their own line of personalized garments for B2B businesses. Grumax manufactures a wide range of products including t-shirts, shorts, sports bras, cycling jerseys, leggings, and more recently has diversified into high performance mattress covers.

With a commitment to continuous improvement and always striving to exceed customer expectations, Grumax is driven to become one of the leading manufacturer of sports apparel in Mexico.

“As we continue to make improvements in our operations, it was clear that continuing to plan using excel spreadsheets was not an option and we needed a system that would allow fast, accurate and detailed planning.

Francisco Cuyas, Chief Executive Officer

This in turn will help us to standardize our procedures, compress our lead times and reduce the time and effort required to execute the planning and purchasing activities. We operate in an increasingly complicated manufacturing environment and having the proper tools is a must to grow our business.”

Grumax

Coats Digital’s FastReactPlan is a market-leading planning and control solution, FastReactPlan, provides a unique, highly visual platform where all areas of the business can simultaneously and dynamically determine the current situation considering the three key planning criteria: capacity, pre-production activities and raw materials availability. The software is a modular solution, configured to meet the specific requirements of each customer.

The solution for Grumax incudes line level planning of sewing, scheduling of secondary operations such as cutting and sublimation, a dedicated planning board for product development activities. It will provide clear priorities and early warning of issues, linked to the planning of the production, so that planners can easily identify the problems and determine corrective actions required to efficiently meet customer deliveries. The system will also include full materials requirements planning (MRP) and a KPI Dashboard provides immediate management visibility of the key drivers of business performance, with drill down for further detail.

“We believe that the increasing demand from the global brands to reduce lead times, maintaining a strong delivery performance is an opportunity for our region where we should leverage our geographical proximity to the US market. In order to achieve this, apparel manufacturers need to switch from the current highly manual planning methods and Excel spreadsheets, to solutions that can quickly plan, identify potential problems early in the process and provide an effective way of ensuring that all departments are working to the same priorities.”

Oscar Gonzalez, Fast React’s (now part of Coats Digital) Agent

Mexico and Central America

Oscar continued, “At FastReactPlan, we are very happy to have the opportunity to support Grumax in their efforts to increase their competitive advantage. We are confident that our planning and control system will provide Grumax with the tools required to improve the control of their product development, raw material sourcing and production planning whilst at the same time reducing their lead times and costs.”

Related testimonials

South Asia

#ProductionPlanning

Birdy Exports of Bangalore improve efficiency with FastReactPlan

“We are confident that from the visibility and coordination FastReactPlan has brought to the business, it has contributed a minimum…

South Asia

#ProductionPlanning

Epyllion increases delivery performance by 58% with FastReactPlan

The use of the integrated Critical Path management tools and the high-level control tower view for management and marketing teams…

South Asia

#ProductionPlanning

KDS Garment Industries in Bangladesh Implement FastReactPlan

“It was very user-friendly, it took us two days to create the masters and then by the next hour it…