Control your biggest expense by combining your fabric cutting and buying operations.

Stop wasting fabric and start increasing profit.

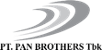

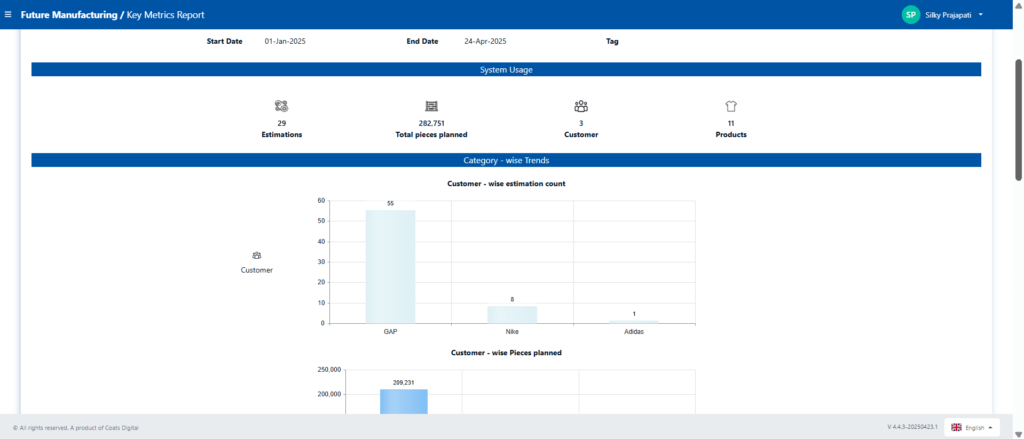

FastReactFabric is a fabric planning solution that uniquely connects your fabric buying and fabric cutting operations into a single platform. This combination is the only way to gain the insights you need to track real-time fabric usage and wastage and efficiently plan for complex styles and colorways. FastReactFabric is the leading fabric consumption software trusted by garment manufacturers around the globe.

The result? Reduce fabric cost, improve fabric use, boost efficiency and increase profit.

Trusted by customers globally

Typical business benefits

90 %

Reduce fabric planning and buying time

2.5 %

Reduce fabric cost

100 %

End to end fabric planning

Combine Your Fabric Cutting and Buying Operations with FastReactFabric

Buy with Accuracy

The buy module of FastReactFabric delivers the most accurate fabric buying forecasts by applying advanced intelligence to your data. These insights help you quickly overcome the challenges caused by complex new styles, increasing colorways and shrinking lead times.

FastReactFabric’s Buy capabilities keep you on top of your fabric needs and booking processes.

- 360-degree feedback loop: Complete loop between cutting and booking to accurately estimate fabric requirements for new buys.

- Speed and accuracy: Process numerous styles at once using big data to ensure quick turnaround in shortened lead times.

- CAD integration: Integrate with different CAD software to provide instructions for marker-making and reduce manual errors.

- Estimation versions: Flexibility to run provisional and actual estimations and use a final version for booking and cutting.

- Intuitive reports: A wide range of excel-based reports and KPI reports that empower you to make critical business decisions.

Cut with Confidence

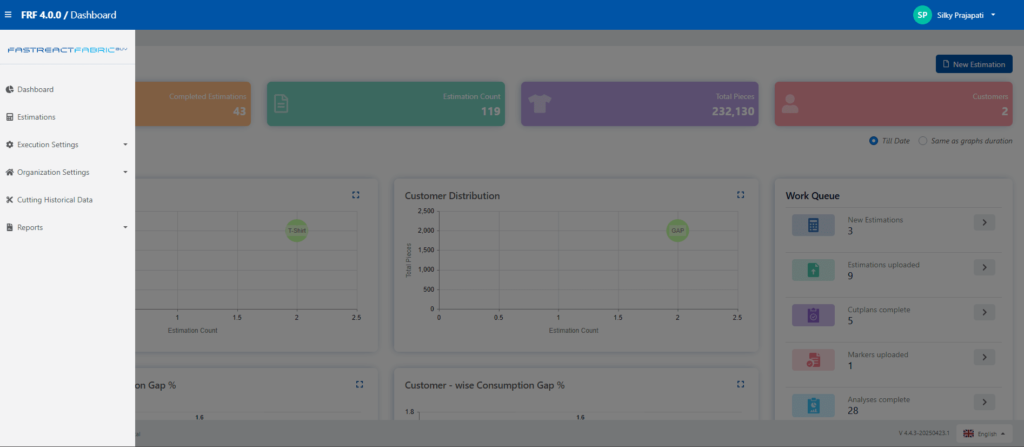

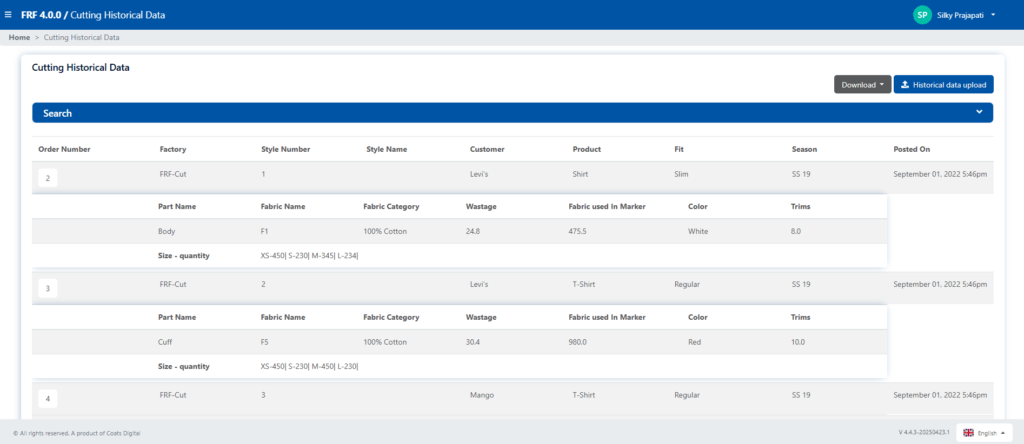

The Cut module of FastReactFabric uses advanced algorithms to generate optimised cut plans from millions of possible combinations with one click. You gain complete control over your cutting room by optimising key processes including the generation of cut and lay plans and allocation of fabric.

The result? Efficient cutting plans that remove bottlenecks and reduce remnants.

FastReactFabric’s Cut capabilities keep you on top of your fabric utilisation.

- Roll Allocation: Reduces end-bit waste in lay spreading by intelligently allocating fabric rolls.

- Endbits Suggestion: Saves fabric by suggesting ways to utilise eligible end bits to the upcoming lays and saving fabric in the roll form.

- Fabric Transfer: Allows the user to transfer fabric lengths from one order to another to increase fabric utilisation.

- Inflection Alert and Replanning: Alerts the user when sufficient end bits are available to meet the fabric requirement and provides an updated plan accordingly.

- Integrates with your ERP: Connect information with your ERP system to reduce manual entries.

Key processes managed by FastReactFabric

Smart Fabric Planning with FastReactFabric

Stop wasting fabric and start increasing profit. Buy fabric with accuracy and cut with confidence.

Customer testimonials

South East Asia

#FabricOptimisation

GJM (Luenthai) cuts fabric wastage to boost its top-line with FastReactFabric

GJM improves their processes to generate real-time optimised plans, fabric tracking and reports with the objective of boosting performance and…

South Asia

#FabricOptimisation

Hoodvian Group automates fabric planning and tracking with FastReactFabric

Hoodvian achieves resounding results with the implementation of FastReactFabric and the group’s continued investment in innovation and digital transformation.

South Asia

#FabricOptimisation

Univogue Group boosts fabric utilisation by 2% with FastReactFabric

The innovative apparel supplier is committed to continuously learning and developing, and investing both human and financial capital, to stay…

South Asia

#FabricOptimisation

Dekko Designs Ltd. gains 1% top-line growth with FastReactFabric

Bangladesh’s leading garment manufacturer Dekko Designs Ltd. chose Coats Digital’s FastReactFabric to implement best practice fabric planning and cutting execution…

South East Asia

#FabricOptimisation

NST to gain 1% top-line growth and reduce fabric wastage with FastReactFabric

By applying advanced technologies to your data along with real-time business intelligence reporting provided by Coats Digital’s FastReactFabric help NST…

South East Asia

#FabricOptimisation

PT. Pan Brothers Tbk. boost their production efficiency by 10% using FastReactFabric

FastReactFabric helped Pan Brothers to implement proper end-bit utilisation and fabric management on the cutting floor leading to significant efficiency…