Paddock’s Jeans improves performance to plan by 8% with FastReactPlan

Paddock’s Jeans has achieved a faster, more reliable order confirmation process and production plan, resulting in improved capacity and critical path management and a significant reduction in reporting time.

Paddock’s Jeans Limited, a sister company of The OSPIG Group in Germany, is a 100% export-oriented manufacturer, located in the Dhaka Export Processing Zone in Bangladesh.

The factory is equipped with its own printing, embroidery, quilting and modern washing facilities with an effluent treatment plant.

Paddock’s Jeans offers a wide range of products such as denim jeans, woven jackets and blazers, for many leading brands including Brax, Bugatti, C&A, John Lewis, Adler, Lee, and Marc O’Polo.

8 %

improvement in performance to plan

10 %

improvement in OTDP

13 %

improvement in critical path (T&A) monitoring

15 %

improvement in capacity forecasting accuracy

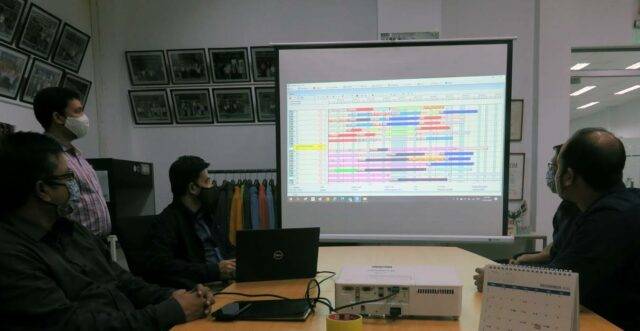

Paddock’s Jeans was using an old light version of FastReactPlan for best practice production planning and control.

In 2019, the company upgraded to the latest version of FastReactPlan, with the aim of further increasing visibility for its Head Office in Germany and across departments to improve forecasting demand versus capacity and On-Time Delivery Performance.

The Challenges

Paddock’s Jeans had a well-established planning process, but there were disconnections in communication and coordination between the departments and a lack of T&A tracking visibility, resulting in a higher deviation between planned and actual production. This led to production backlogs which impacted the company’s capacity utilisation and On-Time Delivery Performance.

The factory’s management had to send the latest production capacity status to their head office in Germany every week. This report was prepared in Excel after considering the required monthly delivery quantity. The process of putting together this report was time-consuming because it required the latest delivery dates of all the orders.

Moreover, factors such as material requirements for the on-time start of production and production efficiency were not considered because of the difficulty in accessing this information, resulting in inaccurate calculation of load versus capacity, with a knock-on effect on delivery performance. The critical path/T&A was managed in Excel by respective merchandisers and departments. This often resulted in poor visibility and coordination because both staff and management had to spend many hours every week in meetings or going through endless reports, emails and excel sheets to clarify the status of orders, identify problems and find possible solutions.

The Solution

The latest version of FastReactPlan gives Paddock’s Jeans deep, specialist planning functionality and provides a flexible, highly visual and intuitive user interface for clear visibility and faster access to the latest information. The best-in-class solution also facilitates fast and realistic planning to set accurate targets for production, considering line skill matrix by product type, learning curve and style SMV. The potential late events/deliveries are colour-coded and highlighted so that the planning team can take early proactive action.

Additionally, with FastReactPlan, Paddock’s Jeans has visibility of performance against daily target plan enabling the planners to work towards reducing the gap between planned versus actual achieved output. This has resulted in an improvement in capacity utilisation by 15% and On-Time Delivery Performance by 10%.

Biswajit Datta, Manager – Merchandising & Sales, Paddock’s Jeans Ltd, commented, “FastReactPlan supports the business improvement process by providing clear visibility and coordination to minimise errors and quickly highlight potential problem areas. By visibly seeing these issues we were able to reschedule in advance, eliminate the requirement to air freight garments, avoid late deliveries and check with customers for delivery extension in advance.

“FastReactPlan is user-friendly and has the flexibility to serve the users requirements. Pre-production planning board T&A is very helpful for our merchandising follow up and realistic planning. The KPI reports in FastReactPlan are used extensively at merchandising and planner level and also for making an informed decision at management level.”

After working with the management team to understand the business challenges, Coats Digital’s team of industry experts recommended Paddock’s Jeans to monitor capacity based on the actual line plan.

This was because all the orders for a delivery month are not always planned for the same month because of variables such as production performance, material availability, order pull forward etc. This helped the factory move from conventional capacity monitoring to dynamic actual plan-based capacity monitoring, giving more realistic production status in open capacity forecasting.

With FastReactPlan, Paddock’s Jeans set up a critical path (T&A) framework in which all key critical path events are included in the system and linked with line planning.

The critical path linked with the dynamic plan gives clear visibility of the latest status of critical path activities to the planner and senior management through the planning board and KPI reports.

As a result, the team now can proactively work on potential issues and take necessary actions to avoid unforeseen issues and firefighting which affect capacity utilisation and impact delivery performance. With FastReactPlan, Paddock’s Jeans has improved critical path (T&A) monitoring by 13%.

Muhammed Rifat Hossain, Implementation Consultant, Coats Digital said, “Being part of a multinational apparel manufacturing company, Paddock’s Jeans has always had to maintain and share numerous reports with the head office which was a big challenge. After the implementation of FastReactPlan, factory teams just need to feed in their day-to-day updates into the system and the system provides all the required reports. The team had a very positive mindset towards the management change they had to go through during the implementation journey which made the realisation of the benefits possible.”

The Result

Teddy So, General Manager, Paddock’s Jeans Ltd. said, “FastReactPlan is the fastest way to check the current capacity and plan based on a realistic scenario. The system has given us clear visibility on operational capacity and T&A status. Previously, it was very difficult for us to get information to manage factory cost, now through accurate KPI reporting we can get data-backed information to make critical business decisions.”

“With FastReactPlan, we’ve realised a 15% improvement in the capacity forecasting accuracy and a 13% improvement in critical path monitoring.”

Teddy So, General Manager

Paddock’s Jeans Ltd.

Golam Khurshed Alam – Planning Manager, Paddock’s Jeans Ltd. said, “Using FastReactPlan, we have established integrated planning through all operational departments. The planning visibility has greatly impacted the decision making in the face of multiple changes, and we can now predict the necessary actions needed to cope with a particular situation. FastReactPlan also helps us to get a more accurate daily output target and is significantly quicker and more accurate than using excel sheets.”

Sharan Kumar Sarkar – Production Coordinator, Paddock’s Jeans Ltd. said, “We have a clear understanding of how to meet the planned target and if the sewing or delivery plan changes, we know what else needs to change to update the plan. This makes our planning process much easier to prevent problematic issues and keep the production lines running smoothly and efficiently.”

“The dynamic reporting tool helps our team to act easily in the required areas. Finally, I would say it’s a “One For All” tool to Plan, Do, Check & Act/Adjust smartly and quickly.”

Sharan Kumar Sarkar – Production Coordinator

Paddock’s Jeans Ltd.

Rukunuz Zaman, Project Manager, Coats Digital said, “We observed that the senior management was actively involved in the project from the very beginning and was keen to improve on how things were managed. The business process was refined, and best practice recommendations were taken positively and established quickly. The result is spectacular which reflects in an 8% better production achievement against the plan and 10% higher on-time delivery performance.”

Developed specifically for fashion manufacturers of all sizes, FastReactPlan is quick to implement and configured to reflect industry best practices and specific business requirements. It is proven to deliver significant and measurable improvements in speed, flexibility, and efficiency.

Related testimonials

South Asia

#ProductionPlanning

Epyllion increases delivery performance by 58% with FastReactPlan

The use of the integrated Critical Path management tools and the high-level control tower view for management and marketing teams…

South Asia

#ProductionPlanning

MAS Active achieve substantial performance improvements with FastReactPlan

The top sportswear supplier dramatically improved performance to plan, increased factory productivity and enhanced customer service

South Asia

#ProductionPlanning

Brandix Group selects FastReactPlan to support strategic initiatives

As the leading apparel manufacturer looks to expand the business, they needed a solution that would strengthen their decision making…