Calculate garment SMV through method-time-cost analysis for sustainable garment manufacturing with GSDCost

Industry standard solution for costing optimisation and method improvement

GSDCost is the international standard for establishing and optimising accurate method-time-cost benchmarks for sustainable garment cost optimisation and manufacturing excellence.

GSDCost supports a more collaborative, transparent and sustainable supply chain, in which brands and manufacturers establish and optimise ‘International Standard Time Benchmarks’ using standard motion codes and predetermined times. This use of a common language and standards supports accurate cost prediction, fact based negotiation, and a more efficient garment manufacturing process, while concurrently delivering on CSR commitments. GSDCost is proven to:

Proven and trusted

GSDCost helps you boost profits

Calculate garment SMV’s accurately with the trusted industry software for method, time and cost improvements. Increase your profits through enhanced collaboration and transparency across the supply chain with GSDCost.

Typical business benefits

5 %

Reduction in SMVs

5 %

Increase in productivity

10 %

Improvement in OTDP

“GSDCost helped us to boost and align our efficiency globally. We can now use more accurate information in our business, improving our sewing method and standardising the sewing process.”

General Manager,

PT. Sumber Bintang Rejeki

How it works

Scientific and objective methods analysis

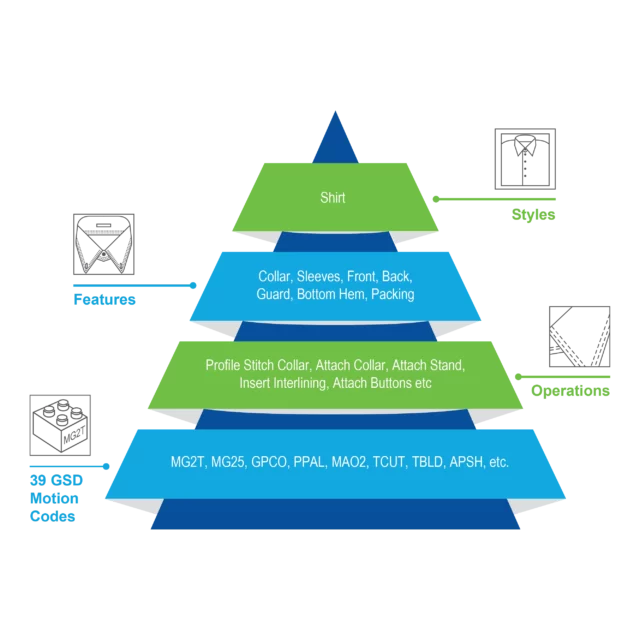

GSDCost is a scientific and objective Methods Analysis process which creates a Method Standard to help establish and optimise ‘International Standard Time Benchmarks’ for all sewn products, using standard motion codes and predetermined times.

It establishes International Time Standards by applying the appropriate Predetermined Motion Codes to each step in the Method Standard.

These 39 Motion Codes, can be used as building blocks to create thousands of operations and features and unlimited product styles.

Key processes powered by GSDCost

What our customers say

Delivering real results

Customer testimonials

Americas

#MethodTimeCostOptimisation

Elcatex Group adopts GSDCost to optimise garment costing

The vertically-integrated manufacturer from Honduras chose GSDCost to quantify and optimise manufacturing methods and garment costing, as a part of…

Americas

#MethodTimeCostOptimisation

Industrias Manufactureras MyR standardise method and cost

Mexico-based garment manufacturer to utilise GSDCost, to drive costing optimisation, manufacturing excellence and business profitability.

Europe, Middle East, and Africa

#MethodTimeCostOptimisation

Egyptian knitwear powerhouse, DICE, reduces its core style SMV by 11% in initial implementation phase of GSDCost

Dice Sports & Casual Wear also gained a 16% increase in production line efficiencies during its GSDCost trial

South East Asia

#MethodTimeCostOptimisation

Leading fashion apparel manufacturer, Shanghai Jiale, reduces its SMVs by over 30% with GSDCost

Following the success released at its Shanghai facility, Jiale Group has begun a GSDCost solution roll-out across its production base…

South East Asia

#MethodTimeCostOptimisation

Nobland International improves productivity by 13% with GSDCost

GSDCost has enabled Nobland to set realistic production goals based on accurate SMVs, resulting in increased productivity and seamless CM…

Americas

#MethodTimeCostOptimisation

RA Intertrading adopts GSDCost for accurate method standard

Coats Digital’s GSDCost enables RA Intertrading to create accurate method standards to optimise workforce processes to meet growing demand